Cold Water Storage Tank Compliance in the UK: Regulations, Standards & Best Practices

Home » Uncategorized » Cold Water Storage Tank Compliance in the UK: Regulations, Standards & Best Practices

Compliance in the UK

Cold water storage compliance in the UK means ensuring your tank is WRAS-approved, meets BS EN 13280, and is maintained to prevent risks such as Legionella. In simple terms, compliance is about storing and distributing water safely while meeting the legal standards set by UK water regulations.

These requirements are not limited to manufacturers. Installers, facilities managers, consultants, and building owners all have responsibilities to ensure that tanks are correctly specified, approved, installed, and regularly maintained. A compliant tank is not only a legal necessity but also a safeguard against contamination, costly system failures, and potential health risks for end users.

For water storage systems, compliance is a combination of three elements: choosing tanks that meet recognised approvals (such as WRAS and BS EN 13280), following correct installation methods, and maintaining them through inspection, cleaning, and record-keeping. When these measures are in place, organisations can be confident that their systems meet regulatory expectations, protect public health, and support long-term operational reliability.

Key Highlights

- Compliance defined: UK cold water storage compliance means ensuring tanks are WRAS-approved, meet BS EN 13280, and are regularly maintained to prevent Legionella.

- Who it applies to: Installers, consultants, facilities managers, and building owners are all responsible for ensuring tanks are compliant.

- Why it matters: Non-compliance risks include health hazards, legal penalties, and insurance claim refusals.

- Key standards:

- WRAS Approval – confirms materials and fittings are safe for potable water.

- BS EN 13280 – sets design and performance requirements.

- LPCB – mandatory for sprinkler and fire protection tanks.

- Checklist available: A 10-point Compliance Checklist PDF is available to download for site audits.

- Lifespan: A properly installed and maintained compliant GRP tank can last 25–30 years or more.

What Does Cold Water Storage Compliance Mean?

Cold water storage compliance refers to meeting the legal and technical requirements that ensure stored water remains safe for use, particularly where it may be used for drinking or come into contact with potable systems. At its core, compliance is about protecting public health, preventing contamination, and guaranteeing that tanks are structurally reliable throughout their service life.

A compliant cold water storage tank must be designed, installed, and maintained to prevent issues such as bacterial growth, leaks, or failures that could put people and buildings at risk. For facilities managers, consultants, and installers, compliance is not just about selecting the right product but also about ensuring proper ongoing management.

Key compliance factors include:

- Approved tank design and materials – tanks must use certified, non-toxic materials (such as WRAS-approved GRP) that are suitable for potable water.

- Correct installation – positioning, base preparation, insulation, and fittings must follow recognised standards and manufacturer instructions.

- Ongoing maintenance – regular inspection, cleaning, and servicing help prevent problems like Legionella and ensure long-term performance.

- Certification and record keeping – proof of approvals, inspections, and servicing should be documented to demonstrate compliance if required by regulators or insurers.

Why Tank Compliance Matters

Cold water storage tanks play a critical role in delivering safe water for residential, commercial, and industrial buildings. When tanks are not compliant, the risks extend beyond equipment failure — they can impact public health, breach legal requirements, and expose building owners to costly penalties.

Health and Safety

Non-compliant tanks can allow bacterial growth, including Legionella, which thrives in stagnant or poorly maintained systems. Contaminated water can pose serious health risks to building occupants, especially in hospitals, schools, and care facilities where vulnerable groups are present.

Legal Requirements

UK law is clear: all cold water storage tanks connected to potable systems must comply with the Water Supply (Water Fittings) Regulations 1999 and relevant British Standards, such as BS EN 13280. Failure to meet these standards can lead to enforcement action from local water authorities or environmental health officers.

Insurance and Liability Risks

If a water-related incident occurs and the tank is found to be non-compliant, insurance providers may refuse claims, leaving building owners liable for damages. Demonstrating that tanks are WRAS-approved, correctly installed, and properly maintained provides clear evidence of compliance, reducing exposure to legal and financial risks.

Key UK Standards for Water Storage Tanks

Cold water storage tanks in the UK must comply with a number of technical and regulatory standards. These ensure that tanks are safe for potable water, structurally sound, and suitable for their intended use. Understanding each standard helps facilities managers, consultants, and installers choose the right tank and prove compliance.

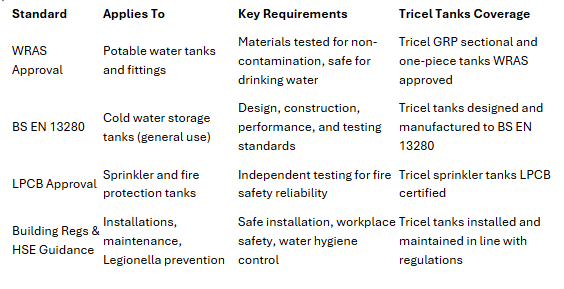

WRAS Approval

The Water Regulations Approval Scheme (WRAS) confirms that a tank and its components meet the requirements of the Water Supply (Water Fittings) Regulations 1999. WRAS-approved tanks are manufactured from tested materials that do not contaminate potable water. To achieve approval, tanks undergo laboratory testing for leaching, mechanical strength, and durability. WRAS certification is essential for any tank used in connection with drinking water systems.

BS EN 13280

BS EN 13280 is the British and European standard that sets performance requirements for cold water storage tanks. It covers design, construction, installation, and testing to ensure tanks can safely store large volumes of water without structural failure. Compliance with this standard provides assurance that tanks meet recognised engineering and safety benchmarks.

LPCB Approval

The Loss Prevention Certification Board (LPCB) provides certification for fire protection products, including sprinkler tanks. LPCB-approved water storage tanks have been independently tested for reliability in emergency use. For buildings with sprinkler systems, LPCB certification is often mandatory for both insurers and fire safety authorities.

Other Relevant Standards

Alongside WRAS, BS EN 13280, and LPCB, tanks may also be subject to requirements under the Building Regulations and Health & Safety Executive (HSE) guidance. These cover areas such as installation standards, workplace safety during maintenance, and Legionella control in cold water systems.

Comparison Table

Compliance Checklist for Cold Water Storage Tanks

To ensure a cold water storage tank meets UK compliance requirements, building owners, facilities managers, and installers should follow a structured set of checks. These confirm that the tank is designed, installed, and maintained to recognised standards.

10-Point Compliance Checklist:

- WRAS Approval – confirm the tank and all fittings are WRAS approved.

- BS EN 13280 Compliance – ensure the tank design and construction meet this performance standard.

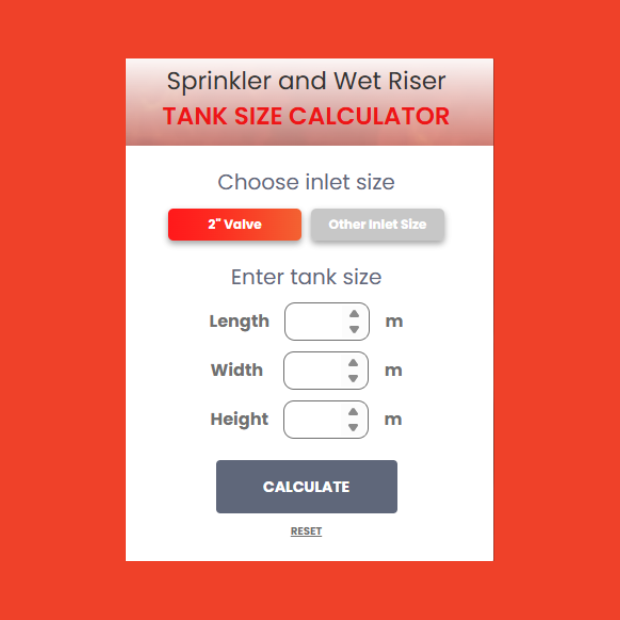

- Correct Sizing – verify the tank has been specified according to building demand and system design

- Structural Integrity – check that the base, supports, and fixings are in line with manufacturer instructions.

- Hygienic Design – confirm the use of non-toxic, smooth-surfaced materials that prevent bacterial growth.

- Insulation – ensure proper insulation to prevent freezing or overheating.

- Access and Covers – verify secure, lockable access covers and safe inspection points.

- Installation Records – keep signed documentation from approved contractors.

- Maintenance Schedule – establish routine inspections and cleaning intervals.

- Logbook and Certification – maintain records of inspections, servicing, and compliance certificates.

Downloadable Resource: A PDF compliance checklist is available for site engineers and facilities managers as a quick-reference tool.

Common Non-Compliance Issues (and Fixes)

Even with clear regulations in place, many cold water storage tanks fail to meet compliance requirements. Non-compliance often arises from outdated equipment, poor maintenance practices, or incomplete records.

Old, Non-WRAS Tanks

Older tanks that were manufactured before WRAS approvals became standard may not meet current regulations.

Solution: Replace with modern WRAS-approved GRP tanks.

Lack of Regular Inspections

Without routine checks, tanks can develop leaks, bacterial growth, or insulation damage.

Solution: Implement annual inspections and cleaning schedules documented in a logbook.

Poor Installation

Incorrectly installed tanks compromise performance and compliance.

Solution: Use approved installers who follow manufacturer guidance and provide commissioning documentation.

Missing Documentation

Even a compliant tank can be flagged as non-compliant if paperwork is missing.

Solution: Maintain a compliance logbook with certificates, inspection reports, and service records.

How to Maintain a Compliant Tank

Step 1: Visual Inspection

Check for cracks, leaks, standing water, corrosion, or insulation damage.

Step 2: Cleaning and Disinfection

Clean at least annually, removing sediment and disinfecting the tank.

Step 3: Record Keeping

Update the logbook with inspections, cleaning activities, and remedial actions.

Step 4: Annual Service

Arrange for a professional inspection and service every 12 months.

Tools & Resources

Yes, all tanks connected to potable systems require WRAS approval.

WRAS covers materials and fittings, BS EN 13280 covers tank design and performance.

At least once a year, more often in high-risk sites.

Yes, enforcement action is possible, and insurance claims may be refused.

25–30 years or more with proper maintenance.

Read More...

- Water Tank Installation & Maintenance

- Cold Water Storage Tanks

- Case Studies

Cold Water Storage Tank Compliance in the UK: Regulations, Standards & Best Practices

Ensuring compliance with cold water storage tank regulations in the UK is essential for safeguarding water quality, maintaining system efficiency, and meeting legal obligations. From WRAS approval and LPCB certification to industry standards such as BS EN 13280, strict requirements govern the design, installation, and maintenance of water tanks.

How to Maintain a Compliant Cold Water Storage Tank

Maintaining a cold water storage tank is not just about ensuring a reliable water supplyit is also a legal and safety requirement. A poorly maintained tank can pose serious risks, including bacterial growth such as Legionella, structural deterioration, or non-compliance with current regulations.

Leak in Water Tank: Causes, Prevention, and Solutions

Water tank leaks can lead to significant structural damage and water loss. Common causes include corrosion, poor installation, and lack of maintenance. To prevent leaks, it's essential to ensure proper installation, use high-quality materials, and conduct regular inspections. For detailed guidance on causes, prevention, and solutions for water tank leaks, refer to Tricel Water UK's comprehensive article.

Importance of Base Levelling Steels

Proper base levelling is essential for the stability and longevity of your water tank. This guide explains why base levelling steels are crucial for preventing structural issues and ensuring your tank performs optimally over time.