WATER TANK INSTALLATION GUIDELINES

Home » Product Guides & Comparisons » Water Tank Installation Guidelines

ASSEMBLY OPTIONS & CLEARANCE REQUIREMENTS for INSTALLING A WATER TANK

Tricel is a trusted manufacturer and supplier of GRP water tanks. We combine technical expertise with years of experience to deliver market-leading water storage solutions.

Our installation guidelines help you choose the right tank assembly method. They also explain clearance requirements for sectional water tanks, making installation easier and safer.

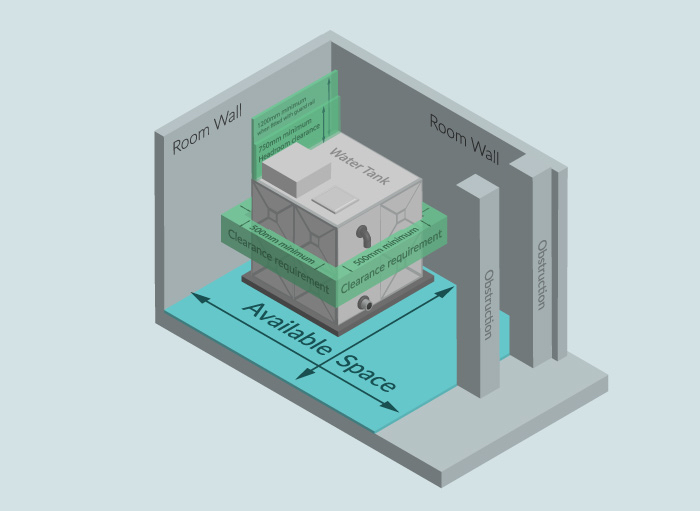

SECTIONAL TANK CLEARANCE

INTERNALLY FLANGED BASE (IFB) TANKS

A minimum headroom clearance of 750mm is needed for hinged access hatches to function properly. However, this can be reduced to 500mm if a lift-off access hatch is installed, following WRAS guidelines. These rules ensure safe and easy access to the tank at all times.

When external ladders or guardrails are installed, a minimum height clearance of 1200mm above the sectional tank is required. This extra space allows for safe movement and proper maintenance.

Clearance Around the Water Tank

For sectional tanks up to 2m high, a minimum internal clearance of 500mm is required.

Tanks between 2.5m and 3m in height need at least 800mm of internal clearance.

For taller tanks, ranging from 3.5m to 4m, the recommended clearance is 1 metre.

These clearances help ensure safe access for inspection, cleaning, and maintenance.

TOTALY INTERNALLY FLANGED (TIF) TANKS

Just like internally flanged base (IFB) sectional tanks, TIF tanks must meet WRAS clearance guidelines. For hinged access hatches to open properly, there must be at least 780mm of space above the tank. However, this can be reduced to 500mm if a lift-off hatch is used instead. This allows maintenance crews to access the tank safely and efficiently.

In cases where hooped external ladders and guardrails are fitted, a minimum of 1200mm clearance above the TIF tank is required. This ensures safe and easy movement during maintenance or inspection.

Where pipework or connections are installed, the clearance on that side must be at least 500mm from the tank’s outer edge. On the remaining three sides, 50mm of clearance is sufficient. This layout allows room for fittings and safe access on all sides.

TIF tanks can be assembled directly on flat surfaces, like plantroom floors. However, the surface must be even. It should not vary more than 2mm in any 1 metre, or more than 6mm across any 6 metres. In addition, the base must fully support the tank’s weight. It also needs to withstand extra loads caused by wind or snow.

WATER TANK INSTALLATION

With decades of experience in GRP water storage, Tricel Weston delivers reliable solutions across the UK and internationally. We offer flexible tank assembly options to suit different project needs.

For international customers with in-house expertise, we provide a supply-only option.

Alternatively, customers can choose our supply-and-install service. In this case, our expert crews handle the full tank assembly on-site. This ensures a fast, professional installation with minimal disruption.

We’re here to support projects of all sizes—wherever you are in the world.

COMPLETE WATER TANK ASSEMBLY

Our experienced teams assemble water tanks directly on-site. Before installation begins, we provide detailed guidelines, including all base requirements. Once the base meets WRAS regulations, our team can begin the installation without delay.

SUPERVISED TANK ASSEMBLY

Tricel Weston can send a specialist and highly experienced supervisor to liaise with the local crew, instructing them and supervising the water tank installation. This ensures the water tank is correctly installed and complies with full warranty instructions.

Read More...

- Water Tank Installation & Maintenance

- Water Regulation

Cold Water Storage Tank Compliance in the UK: Regulations, Standards & Best Practices

Ensuring compliance with cold water storage tank regulations in the UK is essential for safeguarding water quality, maintaining system efficiency, and meeting legal obligations. From WRAS approval and LPCB certification to industry standards such as BS EN 13280, strict requirements govern the design, installation, and maintenance of water tanks.

How to Maintain a Compliant Cold Water Storage Tank

Maintaining a cold water storage tank is not just about ensuring a reliable water supplyit is also a legal and safety requirement. A poorly maintained tank can pose serious risks, including bacterial growth such as Legionella, structural deterioration, or non-compliance with current regulations.

Leak in Water Tank: Causes, Prevention, and Solutions

Water tank leaks can lead to significant structural damage and water loss. Common causes include corrosion, poor installation, and lack of maintenance. To prevent leaks, it's essential to ensure proper installation, use high-quality materials, and conduct regular inspections. For detailed guidance on causes, prevention, and solutions for water tank leaks, refer to Tricel Water UK's comprehensive article.

Importance of Base Levelling Steels

Proper base levelling is essential for the stability and longevity of your water tank. This guide explains why base levelling steels are crucial for preventing structural issues and ensuring your tank performs optimally over time.