importance of base levelling steels

Home » Water Tank Installation & Maintenance » Importance of Base Levelling Steels

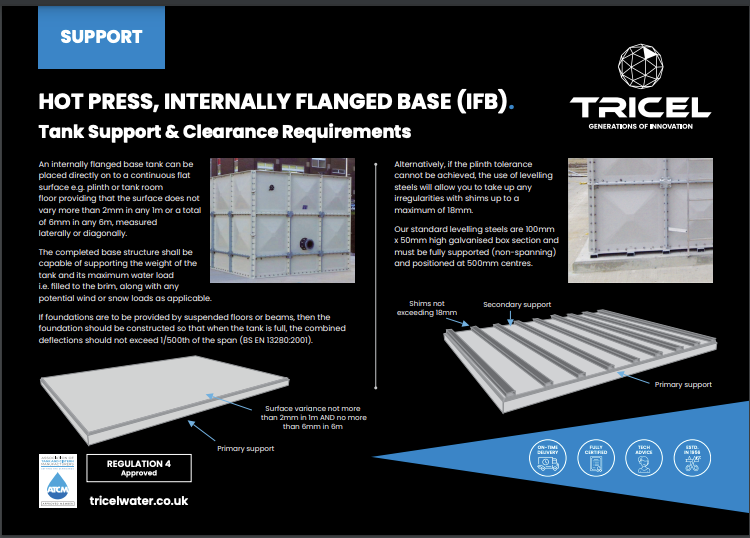

Base levelling steels ensure compliance with BS EN 13280 tolerance requirements. Buying them upfront can significantly reduce abortive site visits and, in turn, offer substantial financial benefits for customers.

Why Should You Buy Base Levelling Steels Upfront?

Why Should You Buy Base Levelling Steels Upfront?

The short answer is to save time and money, but you think that buying base steels upfront will surely cost more money.

Well, the answer is no and here’s why.

Up until a few years ago, abortive site visits were a widespread occurrence and, in the main, down to the fact that the proposed base constructions we were encountering did not meet the tolerance requirements as detailed in BS EN 13280.

Importance of Base Steels

At the time, Tricel always offered base levelling steels, but they were rarely purchased because they were not specified. We were often advised that the tank base is the responsibility of the builder, so why should any M&E contractor pay the extra?

It was a valid point then, but it became clear that the tolerance requirements were rarely achieved. Projects started to fall behind, unbudgeted costs spiralled, and client/contractor relations suffered as a result.

However, at that point in time, the benefit of using base levelling steels was often overlooked. By purchasing them, any irregularities of the existing plantroom floor or cast plinth up to 18mm (+/-9mm) could be absorbed, as our skilled engineers could shim the steels to suit and continue the installation as originally planned.

The realisation that said prevention (buying the base steels upfront) was cheaper and contractually savvy came almost overnight. Granted, it took a while to get to that tipping point, but the cultural shift paid dividends to us all. Not only did the base-related abortive visits almost vanish, fewer building programmes slipped, and unbudgeted costs were significantly reduced. This will result in less hassle for Tricel, contractors, and clients.

So, next time you compare costs and a competitor isn’t including them, is it worth the short-term saving?

GRP sectional Tank Clearance Requirements

How Base Steels meet Tolerance Requirements

BS EN 13280, a European standard that governs the design and construction of water tanks, imposes strict tolerance requirements. Base steels play an important role in achieving these requirements. Adhering to these standards not only ensures compliance with relevant standards but also extends the lifespan of your water storage tank, avoiding the need for an unforeseen water tank replacement.

Aborted Site Visits Due to Poor Base Construction

Over the years, we have concluded that many aborted site visits resulted from poor base constructions that did not meet tolerance requirements. Aborted site visits cause inconvenience and delays, and our client can incur additional costs.

Our experienced site crews can highlight potential issues, including insufficient tank support, an imbalance with the tank weight, inadequate load-bearing capacity, or signs of damage to the tank due to poor base construction. If our site crews identify such issues, this can result in an aborted site visit because further assessments and corrective measures would need to be taken. This process is time-consuming for both our clients and the site crews involved.

Implications of Aborted Site Visits

The implications of aborted visits depend on various factors, such as the nature of the site visit and the size and complexity of the project. However, here are some potential cost considerations related to aborted site visits in our projects:

- Lost time and Productivity

- Rescheduling and Coordination

- Travel and Logistics

Investing in base steels upfront can help avoid costly site visits and repairs caused by non-compliance with BS EN 13280. Abortive site visits, often necessary to rectify mistakes or non-compliance issues, can result in substantial extra expenses and project delays.

Read More...

- Water Tank Installation & Maintenance

- Cold Water Storage Tanks

- Case Studies

Leak in Water Tank: Causes, Prevention, and Solutions

Water tank leaks can lead to significant structural damage and water loss. Common causes include corrosion, poor installation, and lack of maintenance. To prevent leaks, it's essential to ensure proper installation, use high-quality materials, and conduct regular inspections. For detailed guidance on causes, prevention, and solutions for water tank leaks, refer to Tricel Water UK's comprehensive article.

Importance of Base Levelling Steels

Proper base levelling is essential for the stability and longevity of your water tank. This guide explains why base levelling steels are crucial for preventing structural issues and ensuring your tank performs optimally over time.

Water Tank Replacement

Replacing your water tank is crucial for maintaining system efficiency and preventing costly repairs. This guide covers key signs that it’s time for a replacement and the best practices for installing a new tank, ensuring reliable water storage.

Water Tank Installation Guidelines

Ensure your water tank is installed correctly with our comprehensive guide. Learn the key steps, best practices, and important considerations to achieve a successful and efficient installation.